Should your company’s Material Masters seem inadequate, or just plain frustrating, perhaps your mastering process needs a little retooling. It’s easy to drift into a place of complacency when there are so many other company priorities clamoring for management’s attention. But Material Masters are pivotal, performing mightily at the hub of a company’s day-to-day business. So, make no mistake about it, if Material Masters aren’t given due diligence, those relatively insignificant issues might soon blossom into company-wide issues of near epic proportions.

Consider that old-time company managers would’ve loved to have had the ease and control of managing data like company stakeholders have today.

For example, Hollerith cards or what came to be known later as IBM cards or simply punched cards, were created by hand and had no capacity to input data. Instead, cards were placed into what were called input devices—little more than tabulating machines—that took the stored data from each card individually and transferred it into the first rudimentary computers.

The 1890 U.S. census benefitted greatly from the invention of the Hollerith card, completing the job in just two years, thereby saving the government $5 million dollars. Adjusted by Bureau of Labor Statistics figures to the 2019 price index, in today’s dollars that’s well over $133 million dollars saved—due solely to the humble innovation of punching holes in a card to represent reported data. (IBM.com)

Properly regarded, well-crafted Material Masters could in a similar fashion save your company multiple tens of thousands of dollars in a relatively short time.

At the creation level, it is critical that everyone involved understand that the Material Masters should be the system of record for everyone accessing the system from the various departments all the way to the top management and throughout service lines. If precise records are not created and maintained, huge problems may soon develop without stakeholders even being aware just how flawed the data they’re accessing really is, which leads to ongoing issues:

- Increased inventory costs.

- Buyers spending more time than they should on deciphering true inventory versus what the computer system is reporting.

- Departments don’t have visibility to determine detailed spend.

- Executive decision-making based on inaccurate and incomplete data.

POINTS TO KEEP IN MIND ABOUT THE MASTERING PROCESS:

- Material mastering is not data entry.

Relevant subject matter knowledge and understanding is essential for data integrity.

- It’s not unusual for employees involved in the process to receive little or no training.

Untrained employees may overlook or leave out vital attributes necessary for accuracy.

- Due to lack of understanding, lesser value may be placed on the mastering process.

There are questions to be answered/researched throughout the creation of Material Masters that facilitate ongoing functionality:

At the Dictionary level, deciding on necessary abbreviations.

At the Template level, setting priorities for the attributes that are best for

all departments.

At Material Master level, deciding exactly what are the necessary values for each record.

HOW TO FIX THE MATERIAL MASTER PROBLEMS:

Since it is the central repository of information on materials for the business, including what a company procures, manufactures, stores and ships, the end goal of a material mastering process is the creation of a unique description for each material with consistent names for repeated data values with no duplicates.

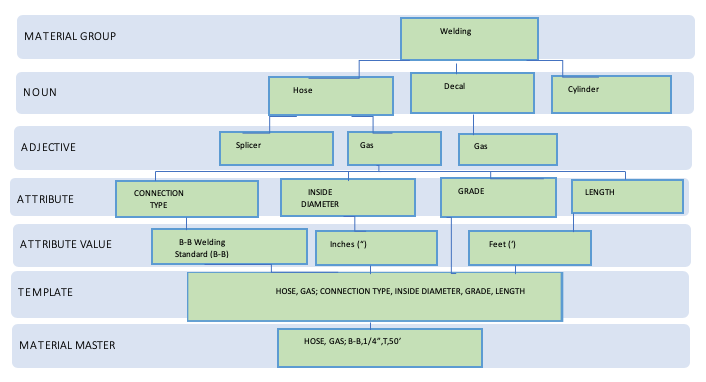

Every Material Master record has five key parts that allow easy search and quick reference in a business: Noun, Adjective, Attributes, Values, Punctuation.

Material Masters Creation

With these key parts in mind and to ensure consistency, companies should put together guidelines similar to these in the following example:

- Create a common list of definitions

- Create a common list of abbreviations

- Create templates for all noun/adjective combinations

- Create agreed-upon guidelines

+Noun/adjective never abbreviated

+Always separate the noun/adjective from the attributes

+Always abbreviate short description attributes

+Use all caps EXCEPT for ‘x’ in dimensions such as 1”x1/2”

+Colors will have 3-character abbreviations

+Sizes are 1 letter with the exception of extra-small which is XS & extra-large which is XL

+Do NOT use XXL, XXXL, XXXXL. Use 2XL, 3XL, etc.

INVESTED PERSONNEL

For consistency sake, it is not advisable to allow unspecified access to Material Masters; a hierarchy of invested personnel should be designated as the go-to gatekeepers to make necessary changes:

DATA MANAGER/STEWARD

- Domain expertise for ongoing Data Governance, Taxonomy & Dictionary

- Data Quality & QC Processes

MASTER DATA CREATOR/BUYER/WAREHOUSE

- Approve standard Material Master creation requests submitted by requestors

- Approve non-standard Material Master & Taxonomy request sent for processing

CATALOGER/PROJECT COORDINATOR

- Create standard Material Master creation requests submitted by fields users

- Update local plant & warehouse level changes in the tool

If the mastering process seems daunting to tackle alone, there is a solution at hand—QuadraDot. We’ll work with your company stakeholders to determine the direction your Material Masters need to go as we assess their current state, the desired state and a plan to get your company to that destination in the shortest but most comprehensive way possible using our Granite Material Masters™ software:

- Develop Governance Structure—Governance is critical for maintaining data quality and made up of: Taxonomy & Dictionary; Processes; Technology; Policies; and Governance Metrics

- Identify Materials to Master—Review current ERP Material Masters for data problems; Review free text materials and identify materials to master

- Standardize Data—Obtain missing data such as vendor and manufacturing information and apply taxonomy

- Load Material Masters

- Develop a Sustainable solution

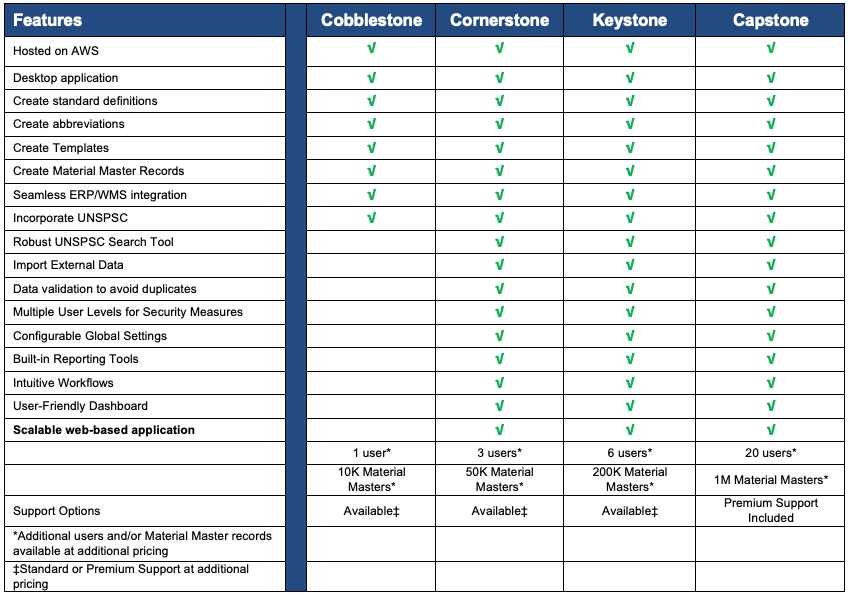

There are four levels of engagement for our Granite software: Cobblestone, Cornerstone, Keystone or Capstone. Depending upon need, there is a level perfectly suited to any sized company:

Happily, the data world has moved on from punched cards, but creating viable Material Masters takes far more than just data entry. Our professionals will help your company build Material Masters to a higher standard, a stance crucial to the ongoing success of any business—your business.